Testing machine for slings

Testing machine for slings

Based on our mobile testing device for chains, we have developed a cost-effective yet fully-fledged, stationary Class 1 testing machine.

We are DYNA-MESS. Testing systems.

Technical characteristics

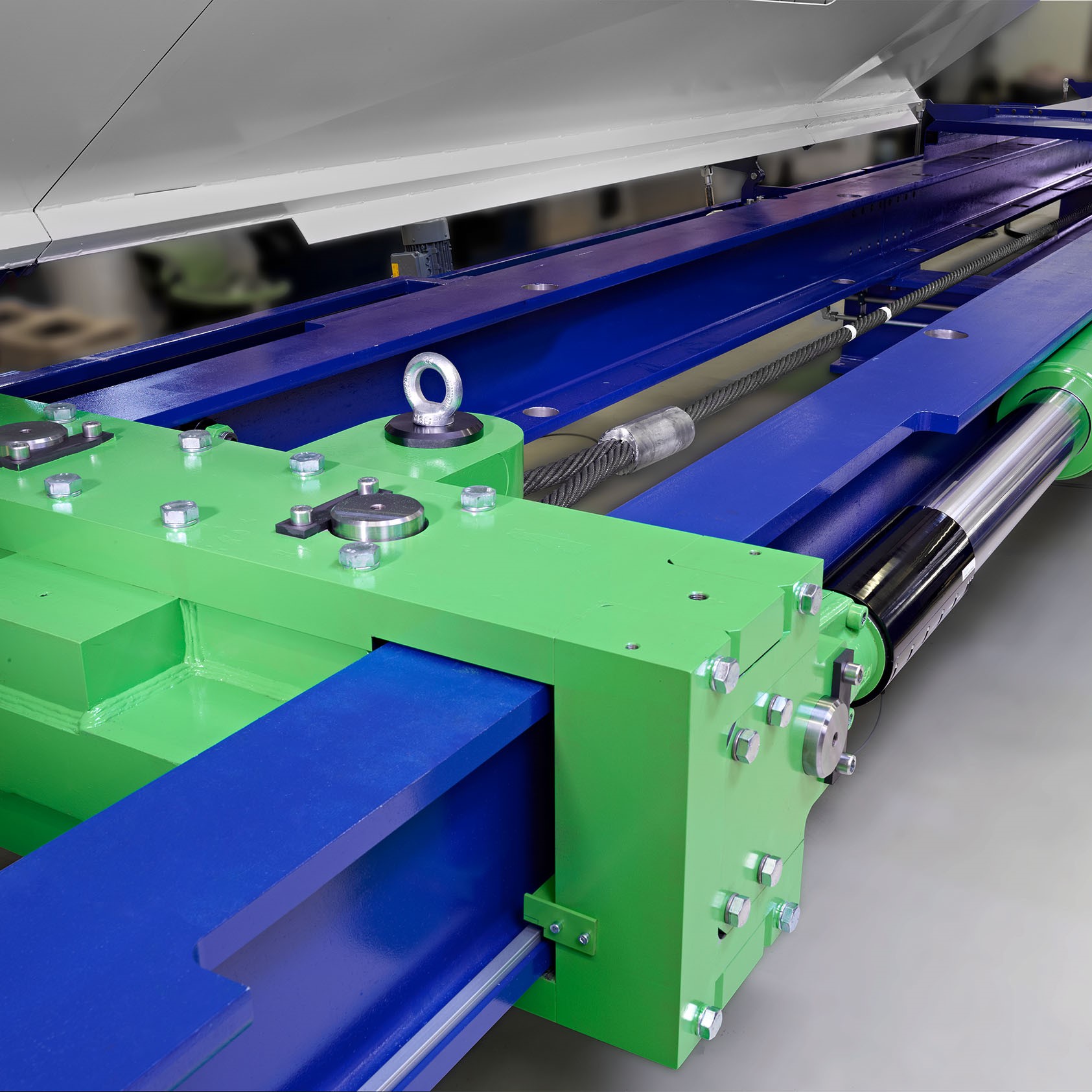

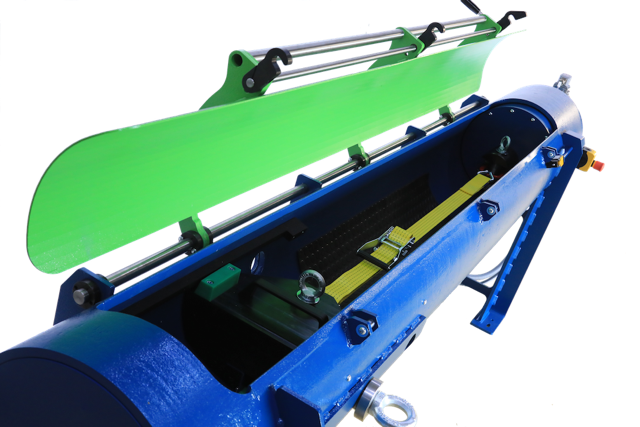

The HH 200 machine is designed for testing slings with loads from 200 kg to 20 t and offers a clamping length of 2 m.

It is servo-hydraulically controlled by our powerful DYNA-CLC testing machine electronics and features direct force measurement with accuracy class 1.

With the DYNA-TCC testing machine software, users can independently configure static and cyclic load profiles, including dwell times. The maximum load speed is 0.6 m/min.

OUR SERVICES FOR YOU

Calibration

Adjusting test systems

Precisely calibrated for reliable measurement results and quality assurance

Maintenance

Maintain test systems

Professional maintenance for optimum performance and a long service life

Repair

Repairing test systems

Repairs for smooth operation and optimum performance

Modernisation

Test systems always up to date

Modern technology for improved performance and accuracy

Accessories

Upgrade test systems

Advanced functions and technologies complete testing machines

Training

Understanding test systems

User and topic training on all aspects of DYNA-MESS test systems

FAQs about testing machines for slings at DYNA-MESS

What is the HH 200 testing machine?

The HH 200 is a stationary testing machine that was developed from the mobile testing device for chains. It is designed for the professional testing of a wide variety of slings under defined loads.

What load range is the machine designed for?

The machine covers a load range from 200 kg to 20 t. This makes it suitable for typical testing tasks in industry, service and workshops where slings are used in safety-relevant applications.

What clamping length is available?

The HH 200 offers a clamping length of 2 m. This means that even longer slings can be clamped and tested comfortably and safely.

How is the drive and control system operated?

The machine is controlled servo-hydraulically via the DYNA-CLC testing machine electronics. This enables precise and reproducible loading of the test specimens with direct force control.

How accurate is the force measurement?

The HH 200 features direct force measurement in accuracy class 1. This enables accurate and standard-compliant test results for documentation and quality assurance.

Which test profiles can be run?

With the DYNA-TCC testing machine software, users can configure static and cyclic load profiles themselves, including hold times. This allows different test requirements to be mapped flexibly and application-specifically.

What services does DYNA-MESS offer?

DYNA-MESS provides comprehensive services:

- Calibration: Adjustment for precise measurement results

- Maintenance: Regular care for a long service life

- Repair: Restoration of operation

- Modernisation: Technological updates to improve performance

- Accessories: Extensions and upgrades

- Training: User training for DYNA-MESS testing systems