Vertical testing machines

Vertical testing machines

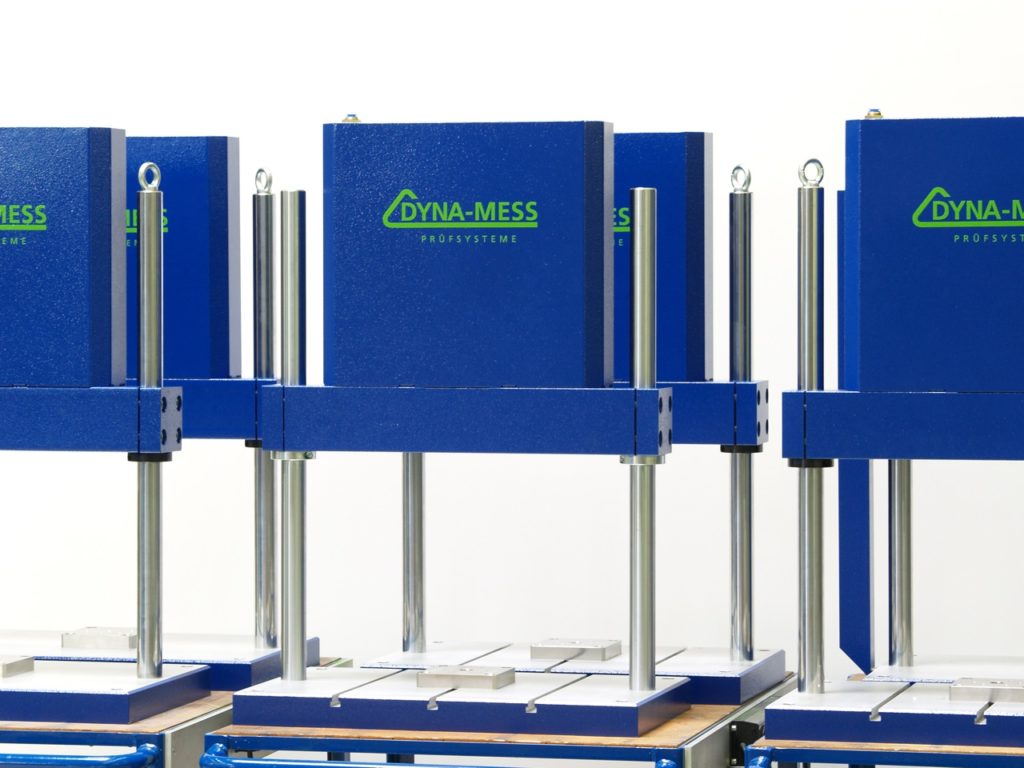

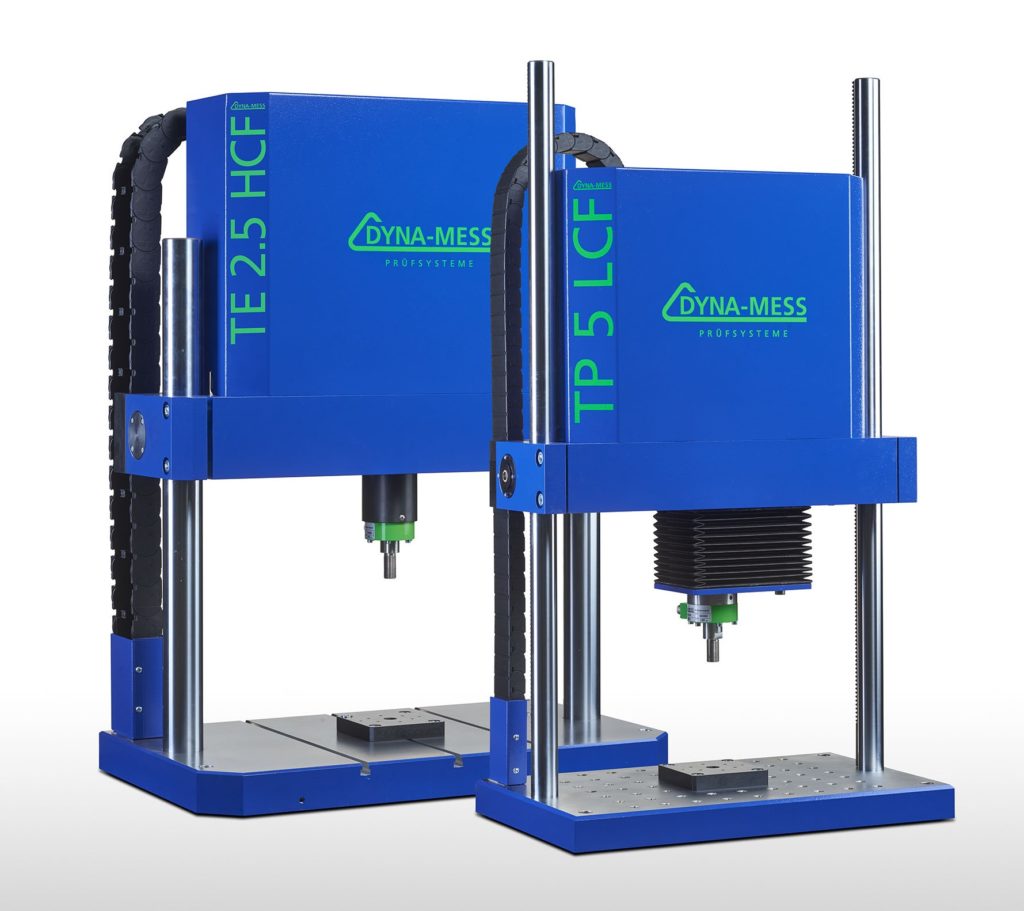

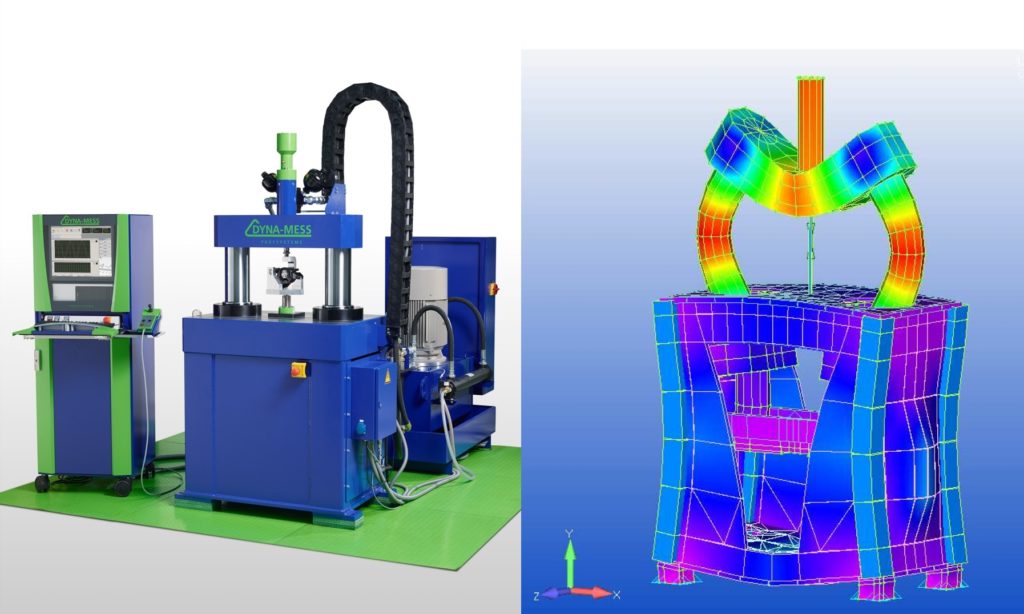

We offer vertical testing machines with servo-hydraulic, servo-pneumatic and servo-electric test cylinders. With 2-column or 4-column test frames, they enable tests with top or bottom-mounted test cylinders for versatile tests.

We are DYNA-MESS. Test Systems.

Technical properties

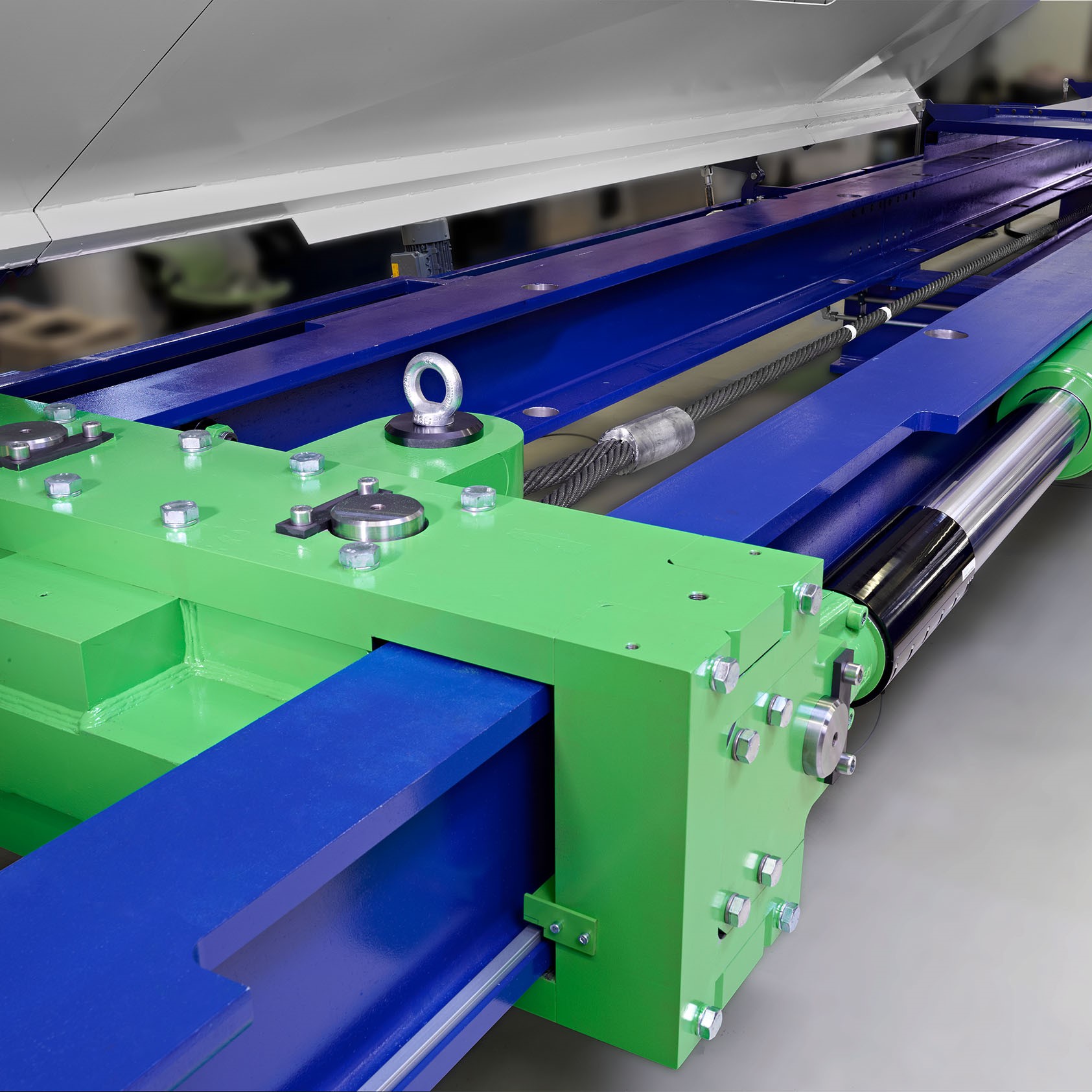

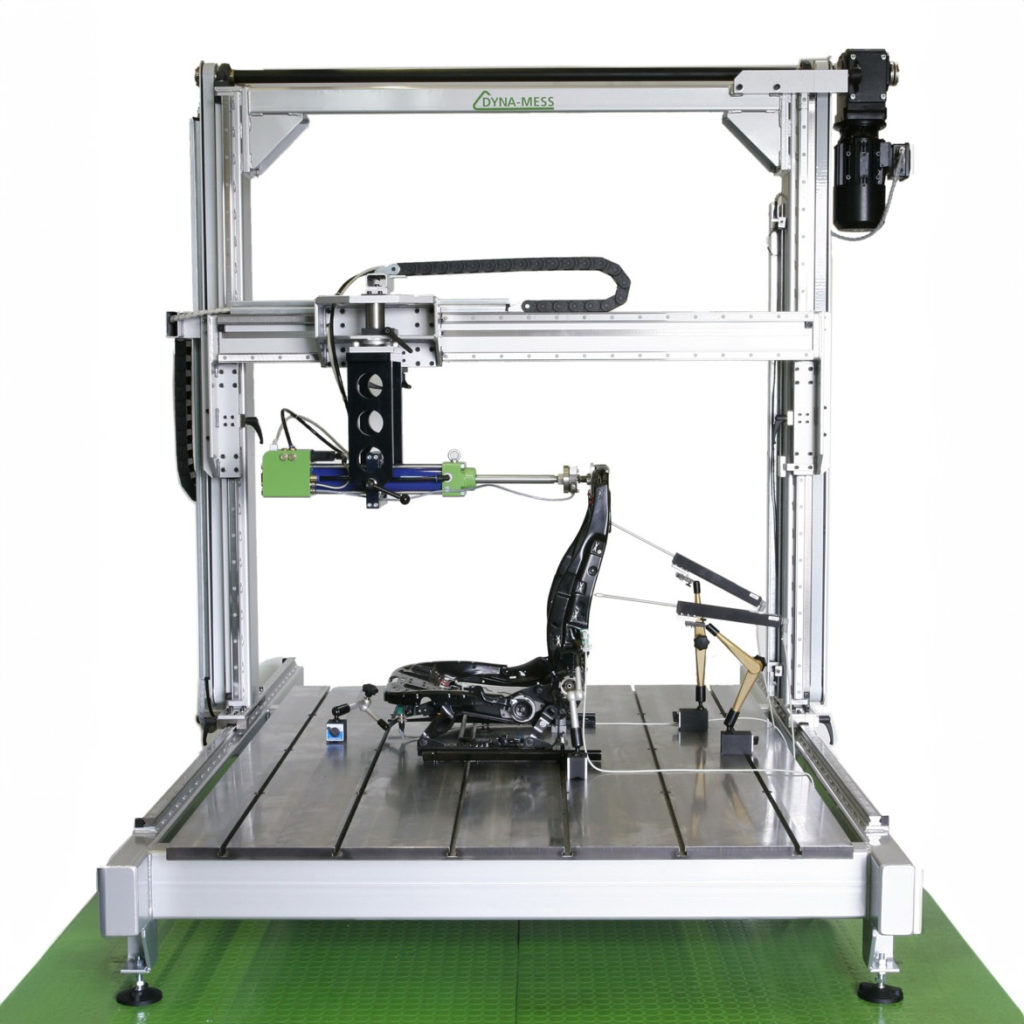

Test frame

The machine frames are designed as a 2- or 4-column construction and are characterised by maximum machine rigidity. They are therefore ideally suited for static and, in particular, dynamic tests.

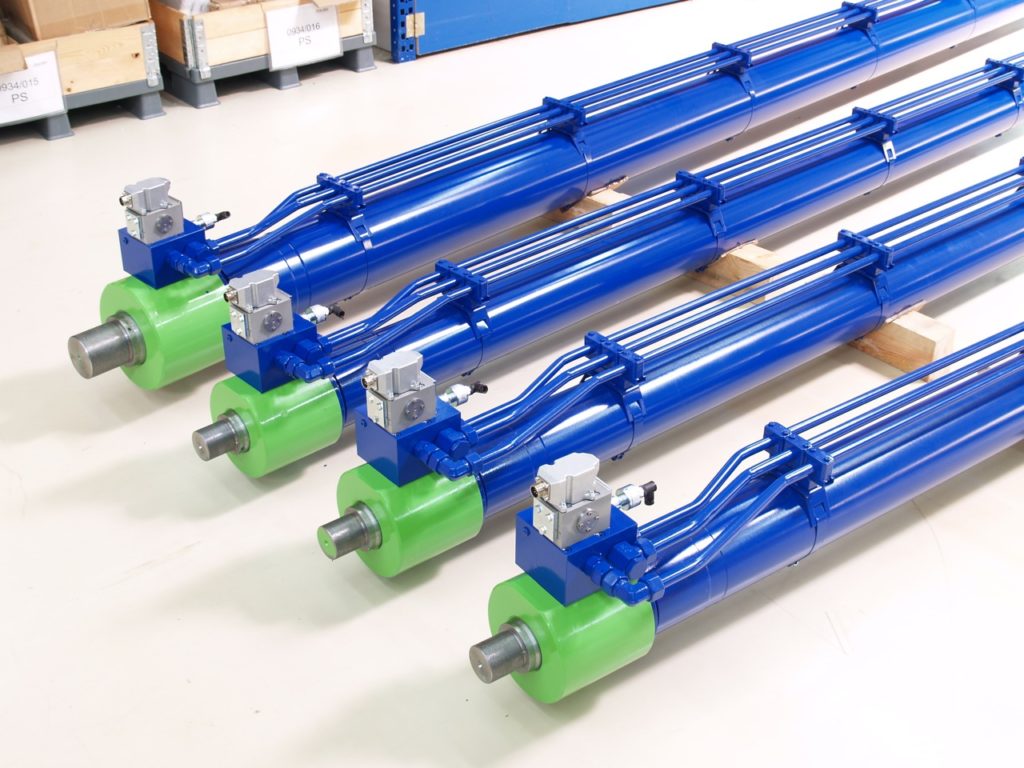

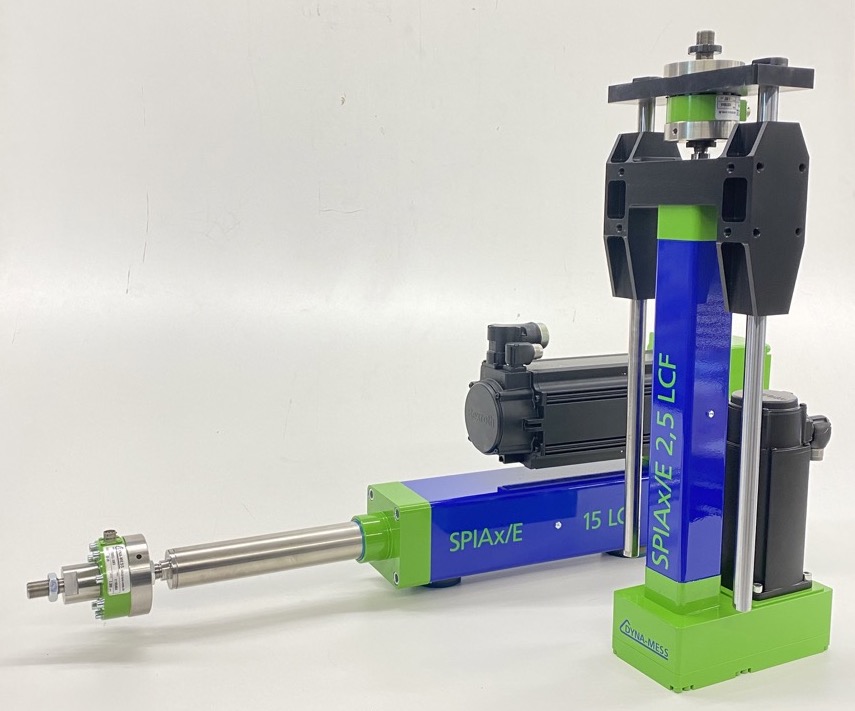

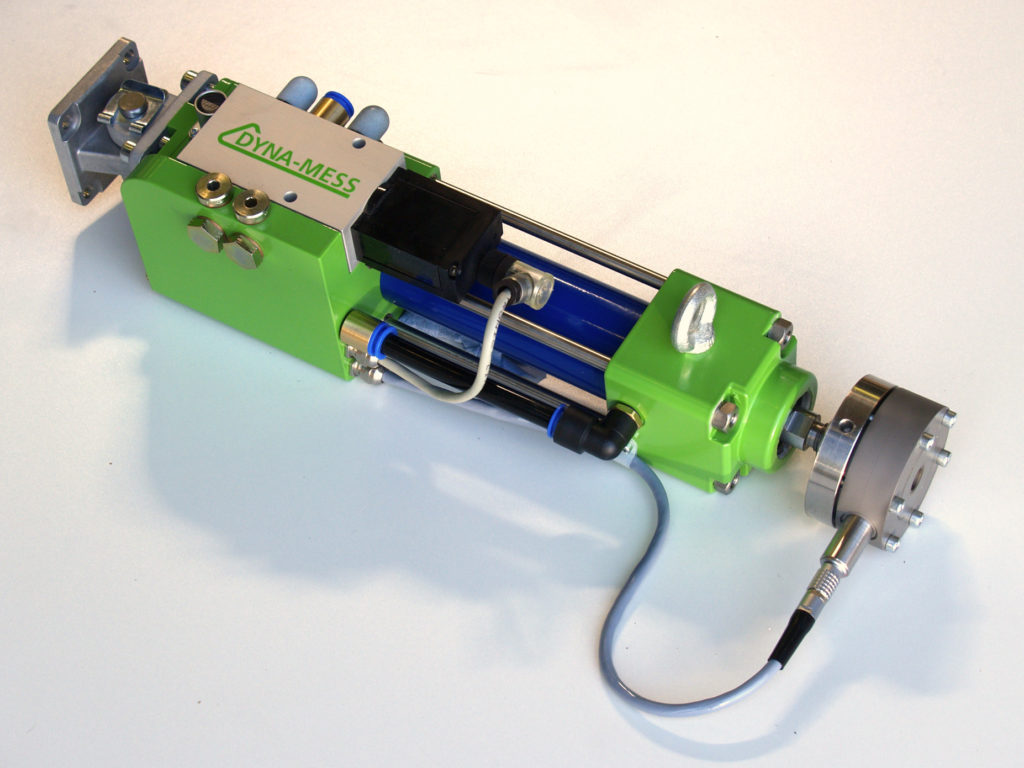

Drive types

The most suitable drive types are used depending on the individual testing requirements of our customers. In addition to the desired nominal force and the required dynamics, aspects such as component behaviour and ambient conditions also determine the selection of the right drive.

Performance capability

With servo-pneumatic, servo-electric or servo-hydraulic drive concepts, we cover a wide range of requirements. The nominal forces range from 10 kN to several meganewtons.

In addition to the machines for purely static testing, variants for low cycle fatigue tests (LCF) for test frequencies up to 10 Hz and for high cycle fatigue tests (HCF) for test frequencies up to 100 Hz are available.

A special version for high-frequency tests is the V2H 10 HCF+ version, which enables tests with frequencies of up to 500 Hz.

Sensors

DYNA-MESS testing machines are equipped with high-precision force and displacement measurement as standard.

Additional measuring systems can be easily integrated.

Tension Torsion version

Tension Torsion describes a combined test specimen load from a linear drive and torsion unit.

Two different configurations are possible:

- Biaxial test specimen load from one side

- Biaxial test specimen load from different sides (one axis in the crosshead and one axis in the machine base)

Electric, pneumatic and hydraulic versions are available.

OUR SERVICES FOR YOU

Calibration

Adjusting test systems

Precisely calibrated for reliable measurement results and quality assurance

Maintenance

Maintain test systems

Professional maintenance for optimum performance and a long service life

Repair

Repairing test systems

Repairs for smooth operation and optimum performance

Modernisation

Test systems always up to date

Modern technology for improved performance and accuracy

Accessories

Upgrade test systems

Advanced functions and technologies complete testing machines

Training

Understanding test systems

User and topic training on all aspects of DYNA-MESS test systems