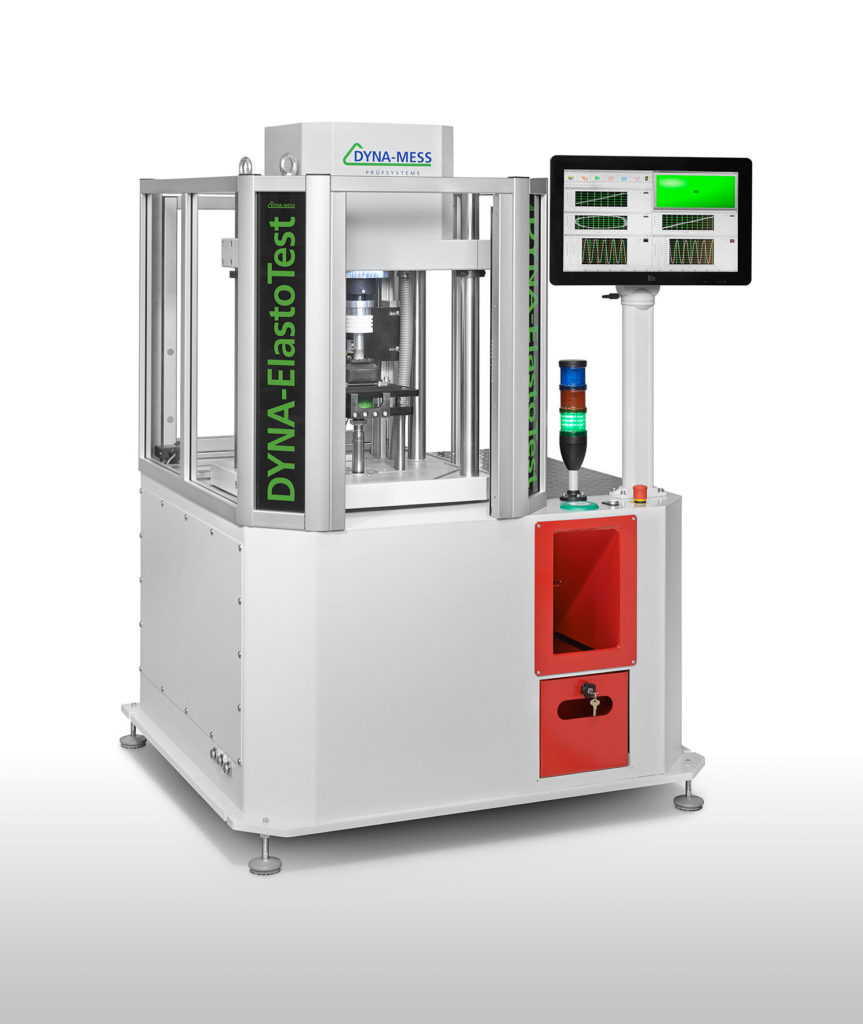

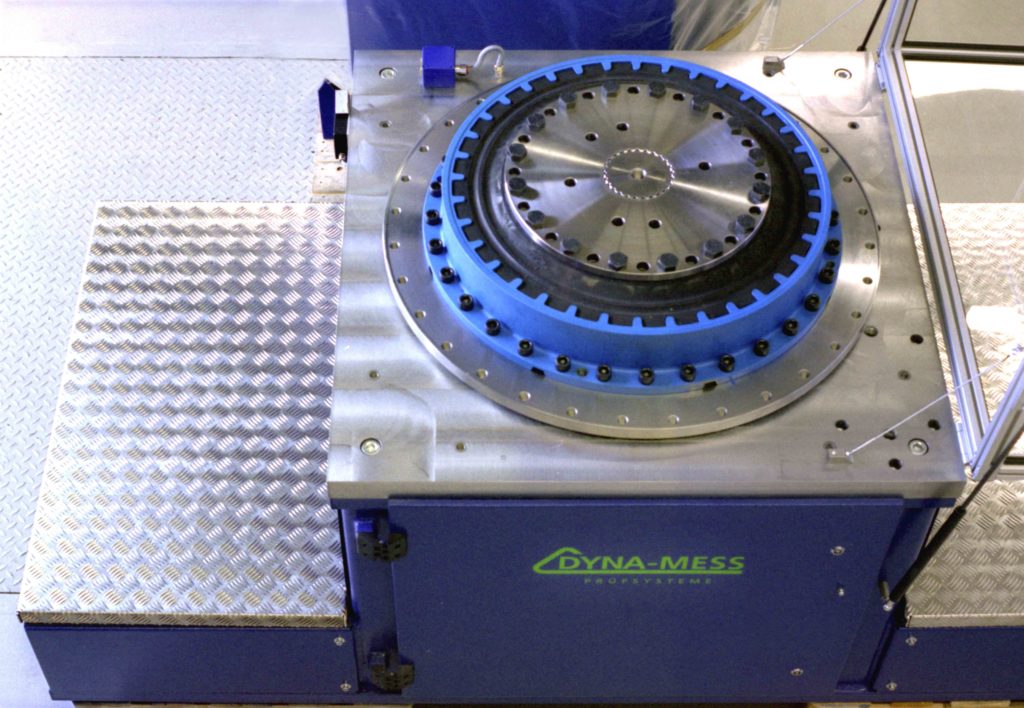

Torsion test rig

Torsion test rig

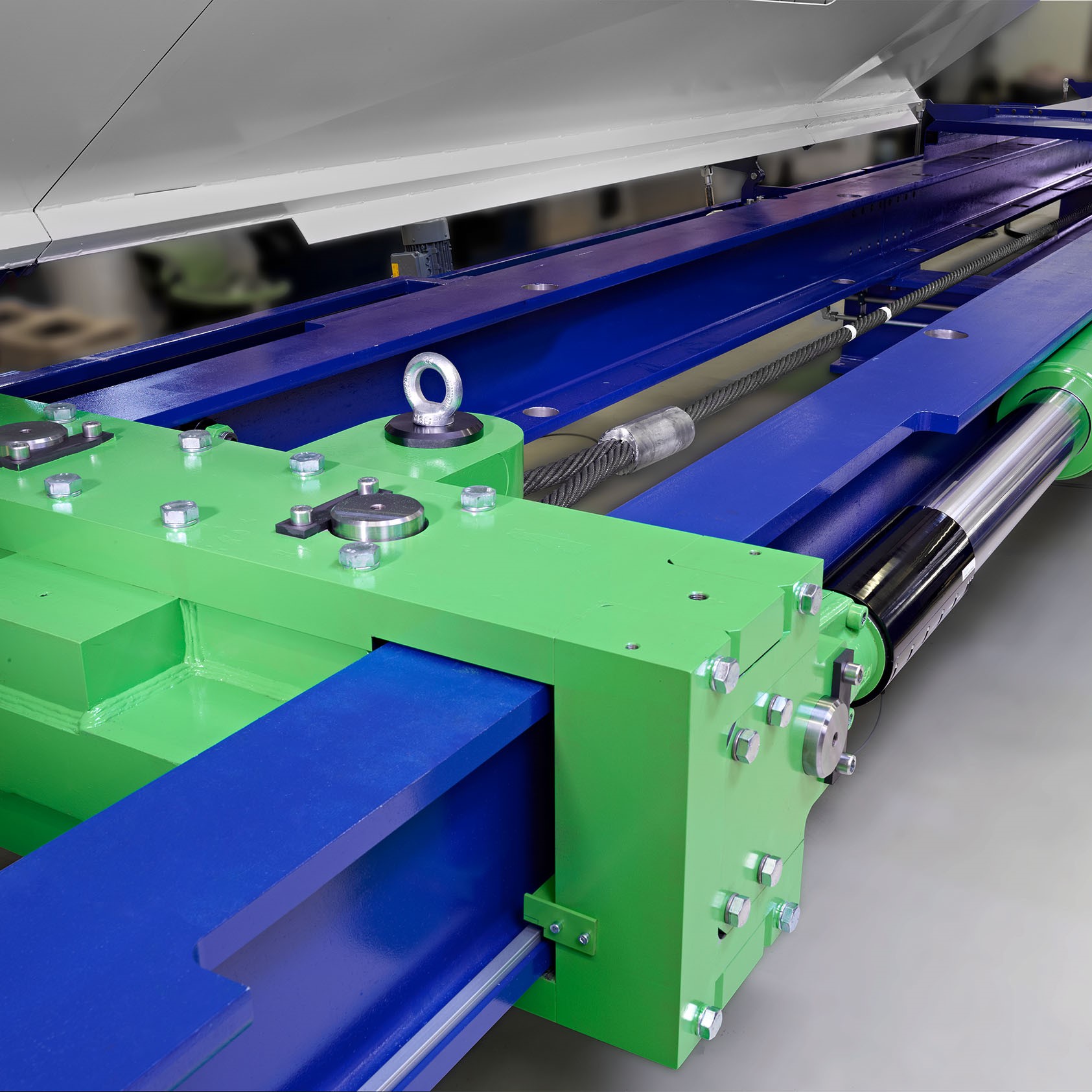

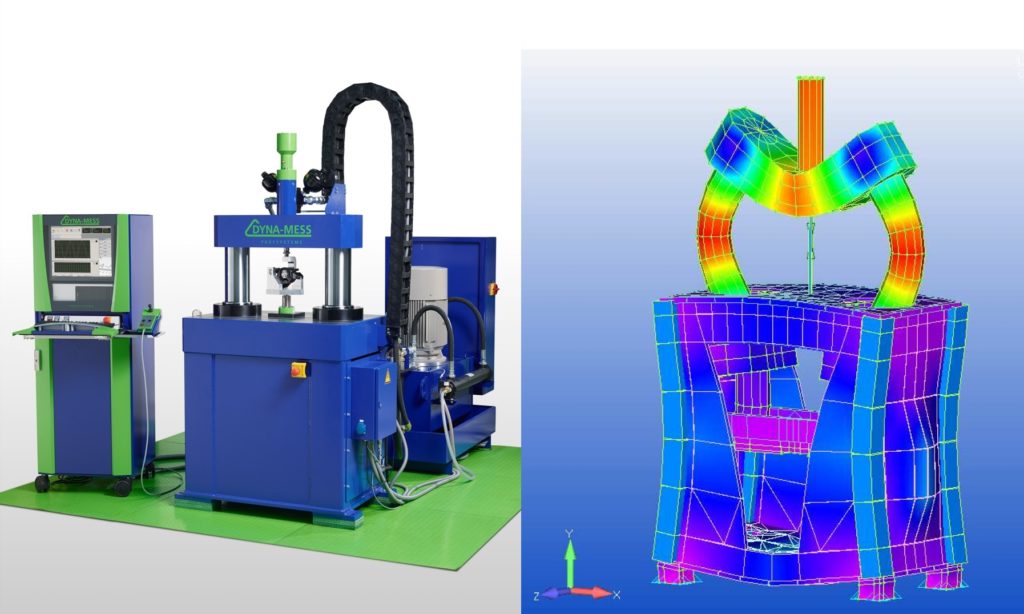

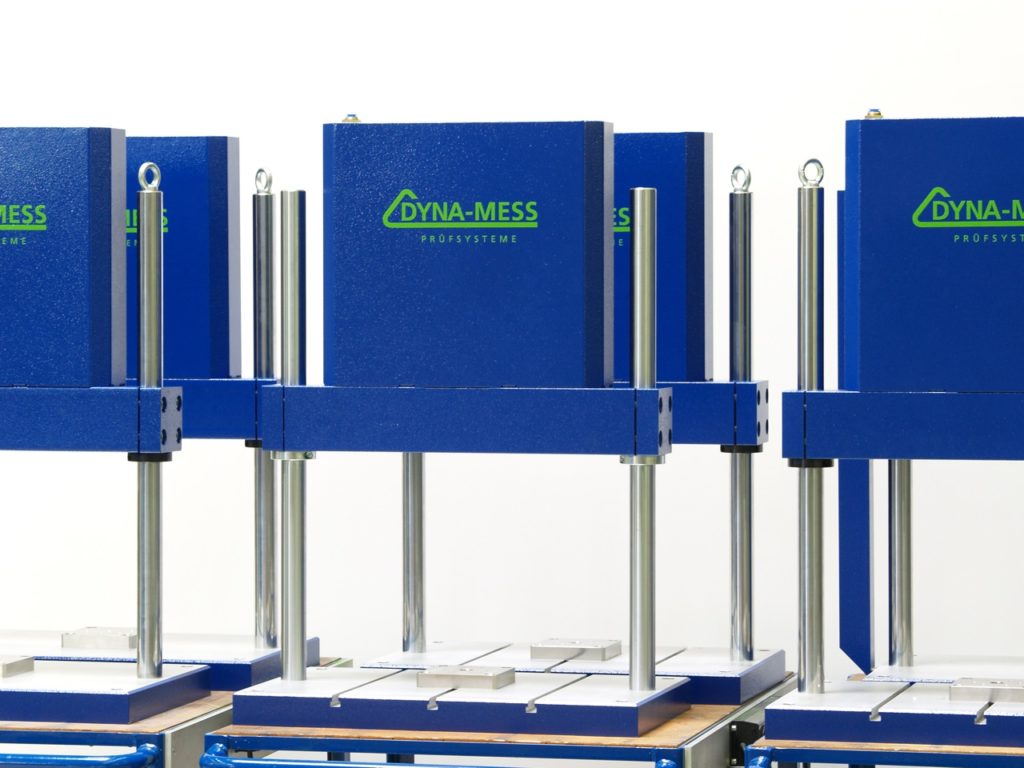

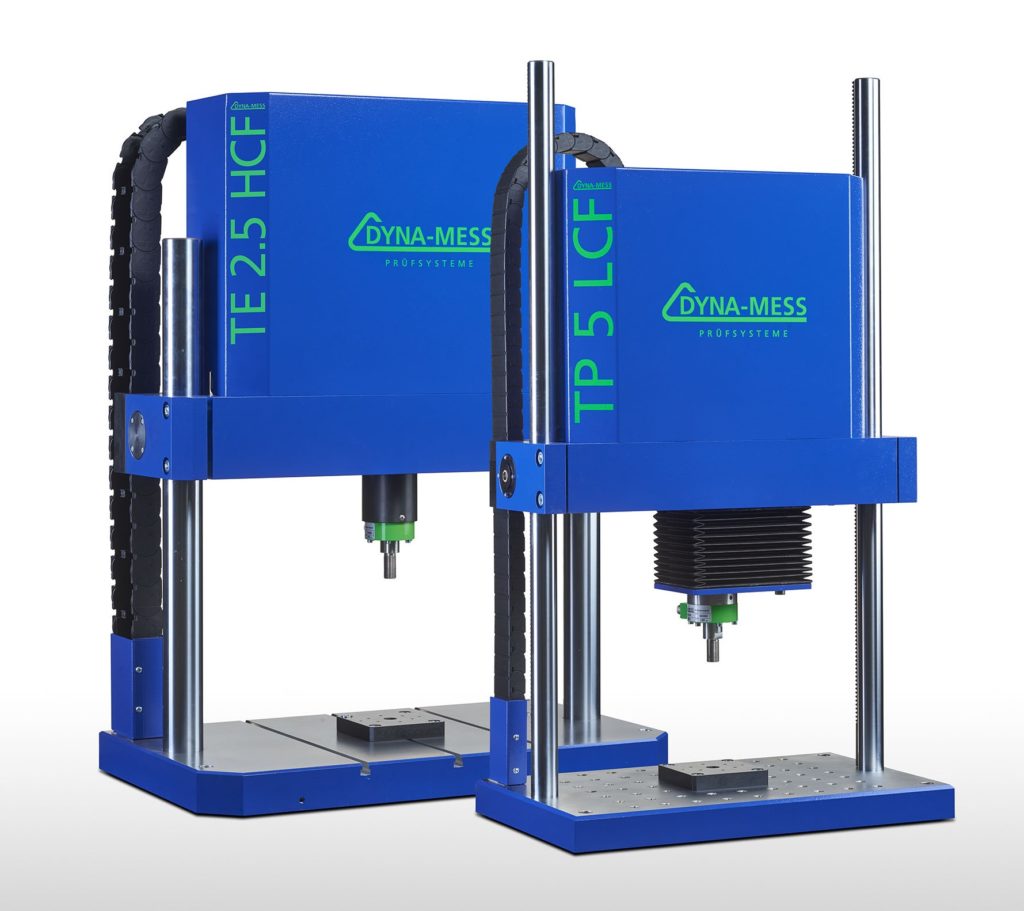

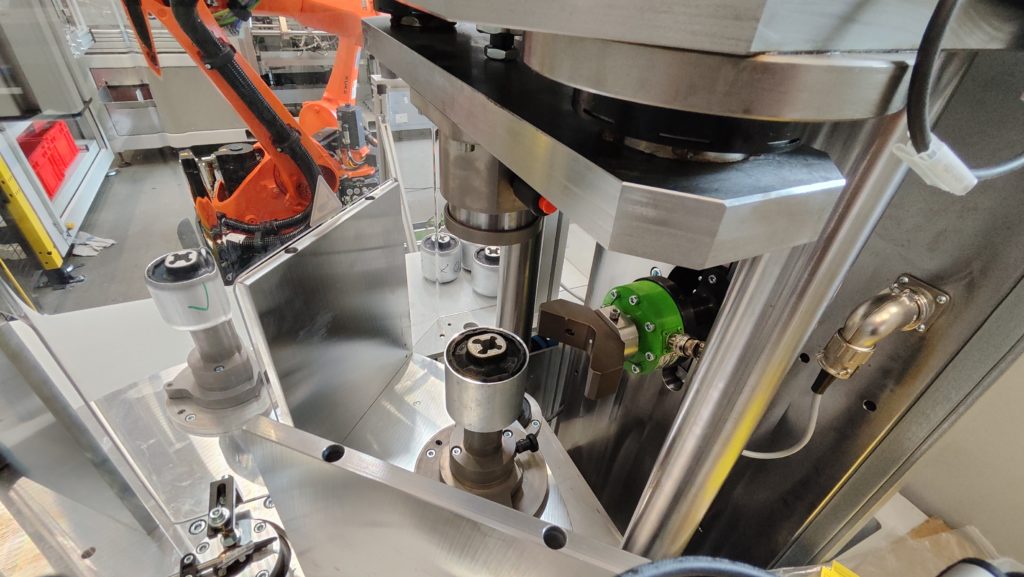

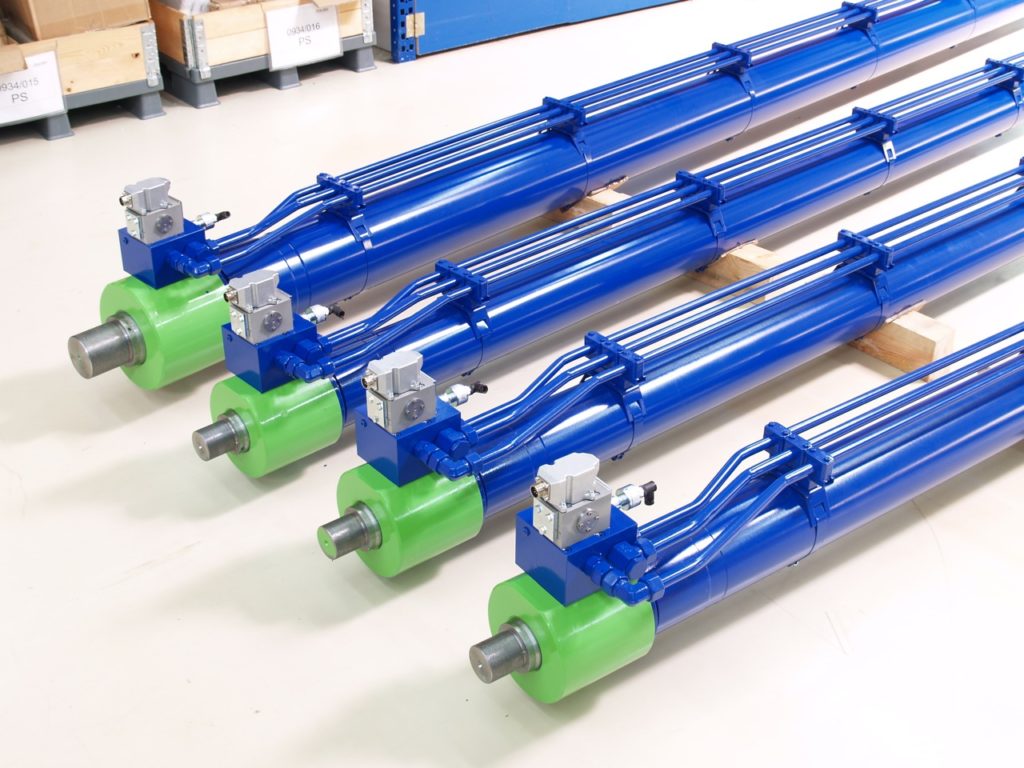

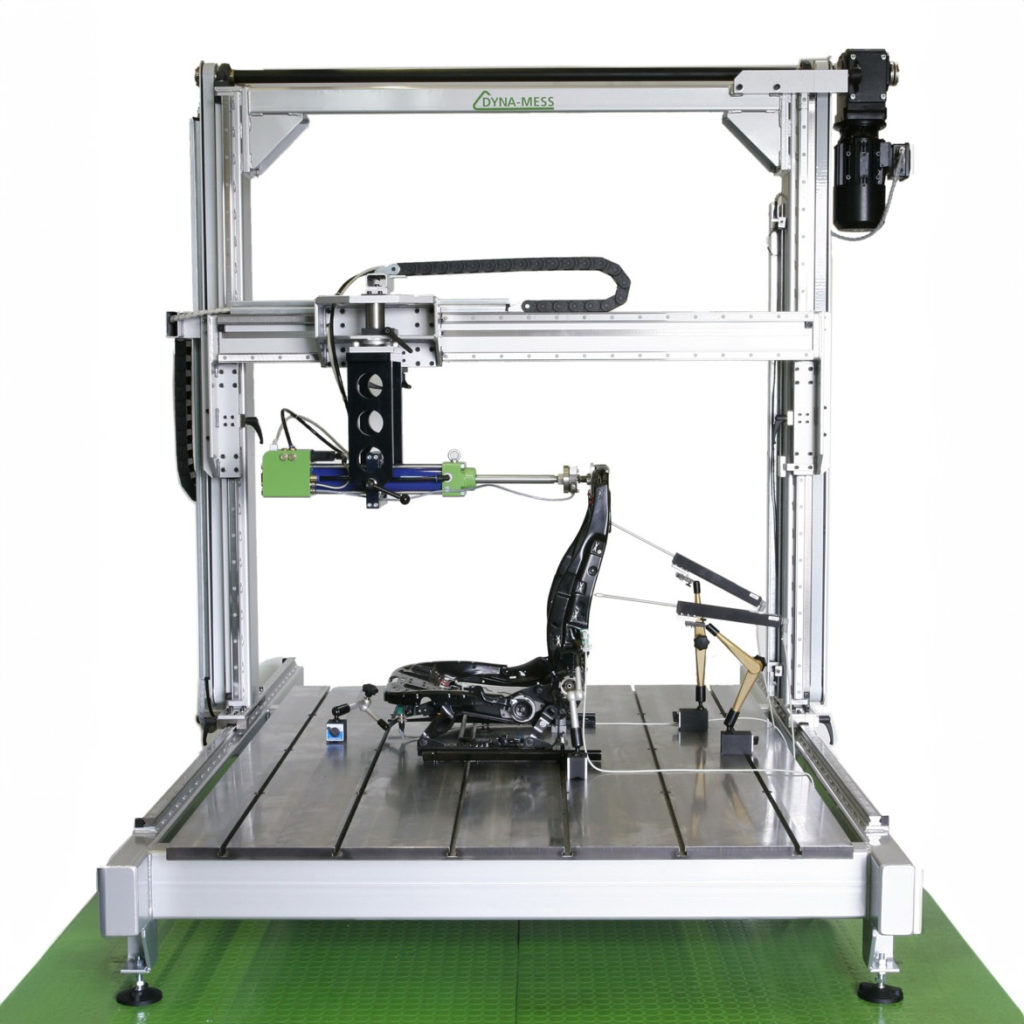

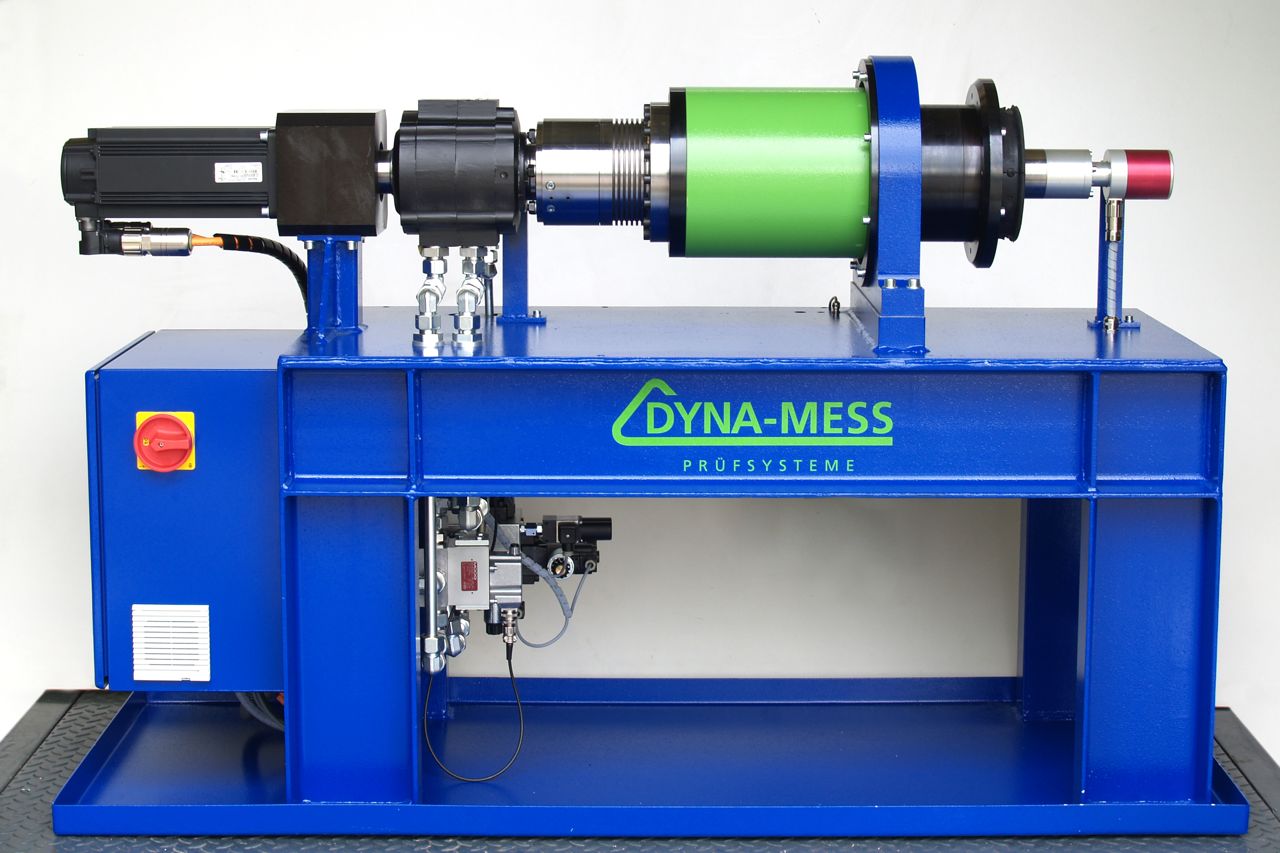

Various components, including vehicle couplings, elastomer couplings, dual-mass flywheels, drive shafts and transmission components, are subjected to torsional loads during operation. These components can be tested on DYNA-MESS torsion test rigs with axial/radial misalignment.

We are DYNA-MESS. Test Systems.

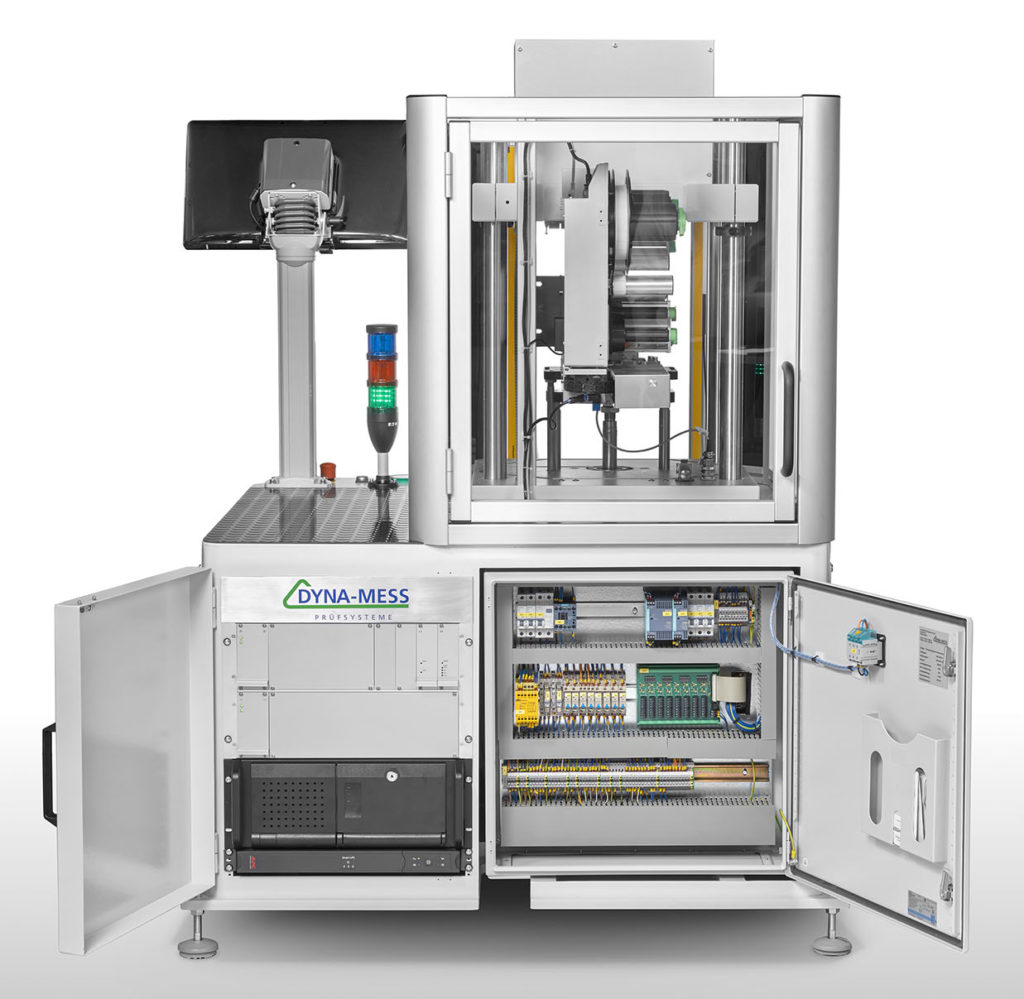

Technical properties

Static characteristic curves and dynamic characteristic values

DYNA-MESS torsion test rigs enable both static load tests up to breakage and dynamic fatigue tests to determine service life. Vibrations can be superimposed on static moments in order to simulate operating conditions. The test benches are also used to determine characteristic values, including the static torsion curve, hysteresis, stiffness at various operating points, dynamic stiffness, loss angle and damping energy.

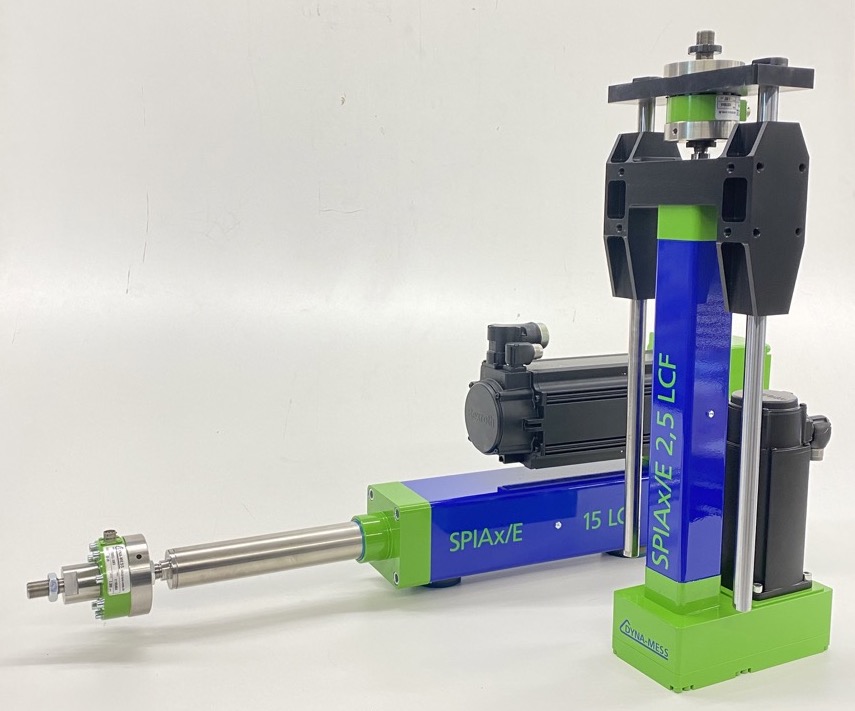

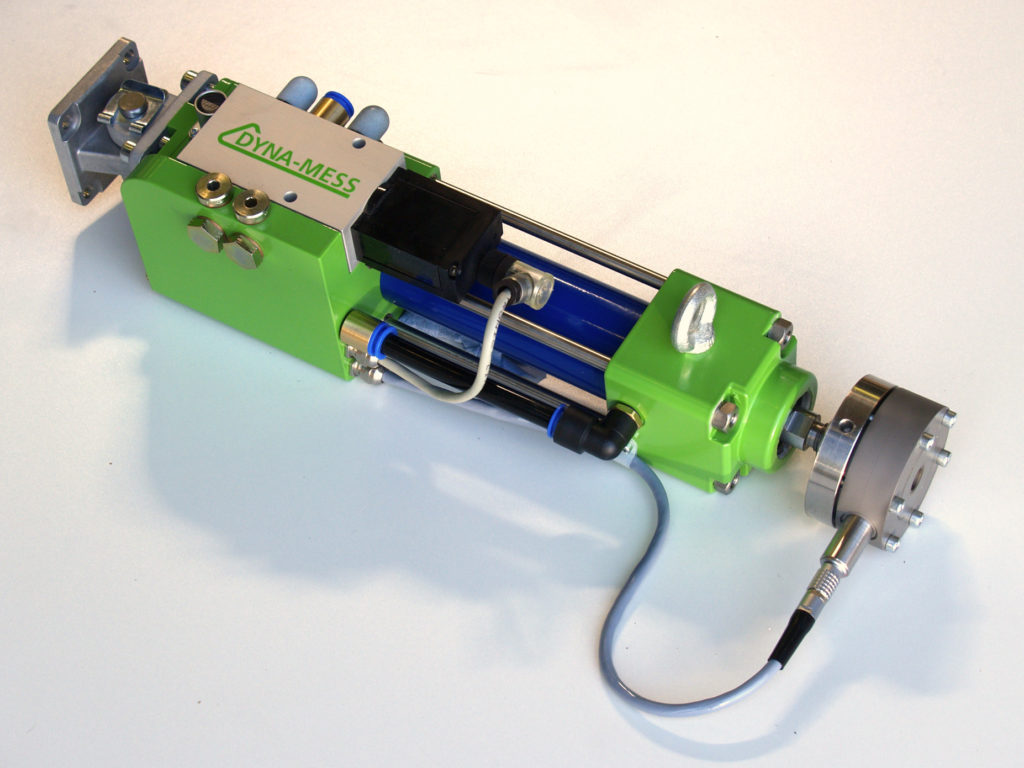

Axial preloads, torsion test rigs and superposition test rigs

Complex test systems for development can be equipped with several superimposed drives if required by the application of the component to be tested. For example, systems with selectable, constant drive speed, to which a vibration load and additional slip between the input and output side is superimposed, have been realised. Classic torsion test benches or torsion test benches with superimposed axial loading are also possible.

OUR SERVICES FOR YOU

Calibration

Adjusting test systems

Precisely calibrated for reliable measurement results and quality assurance

Maintenance

Maintain test systems

Professional maintenance for optimum performance and a long service life

Repair

Repairing test systems

Repairs for smooth operation and optimum performance

Modernisation

Test systems always up to date

Modern technology for improved performance and accuracy

Accessories

Upgrade test systems

Advanced functions and technologies complete testing machines

Training

Understanding test systems

User and topic training on all aspects of DYNA-MESS test systems