DYNA-BAT

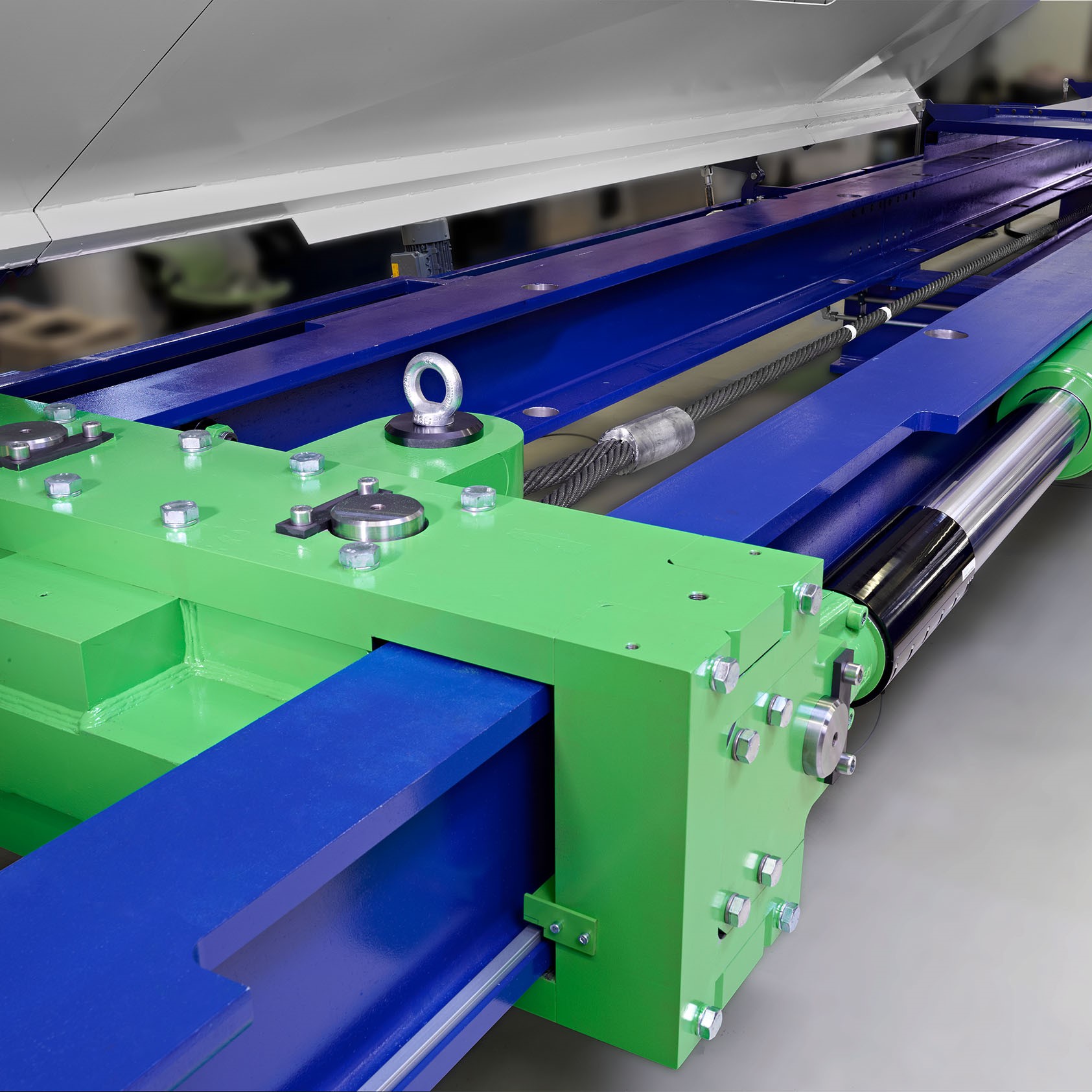

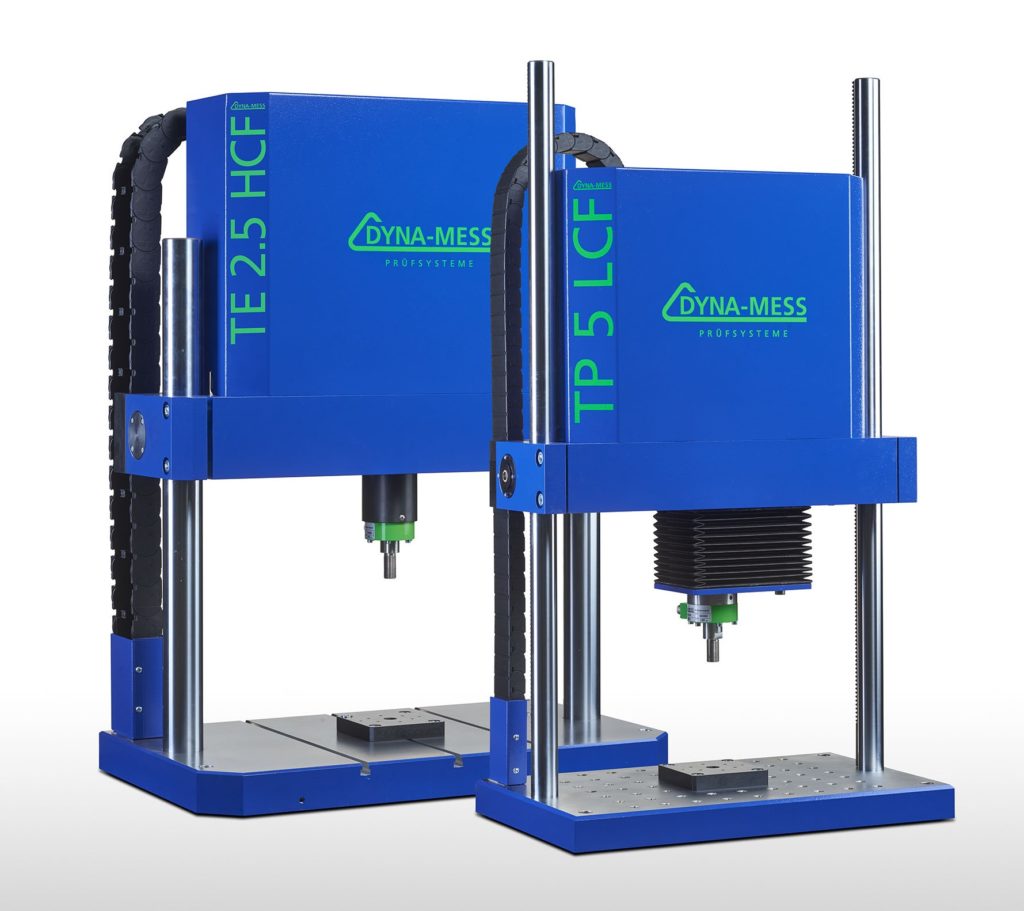

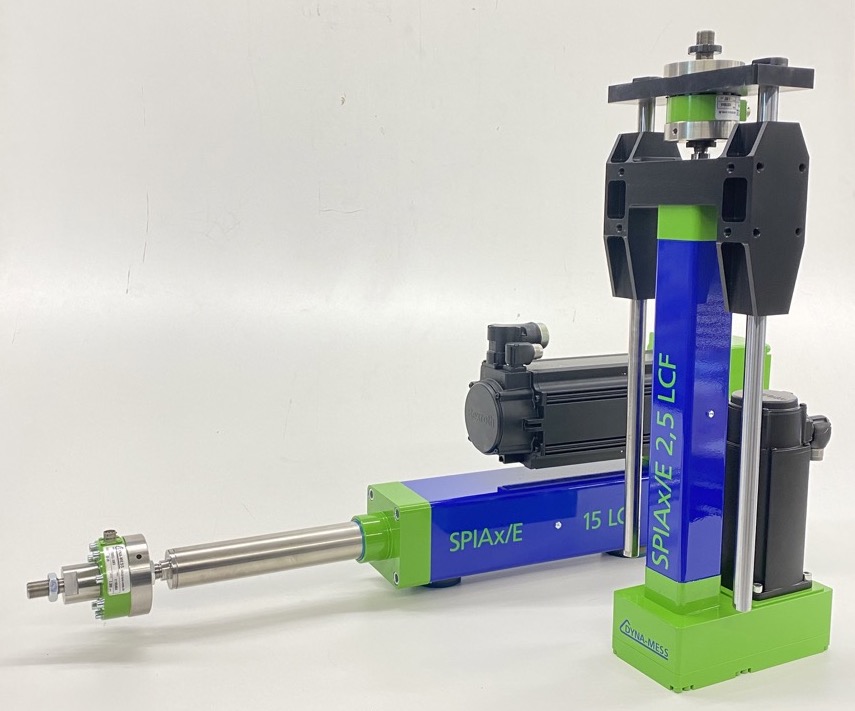

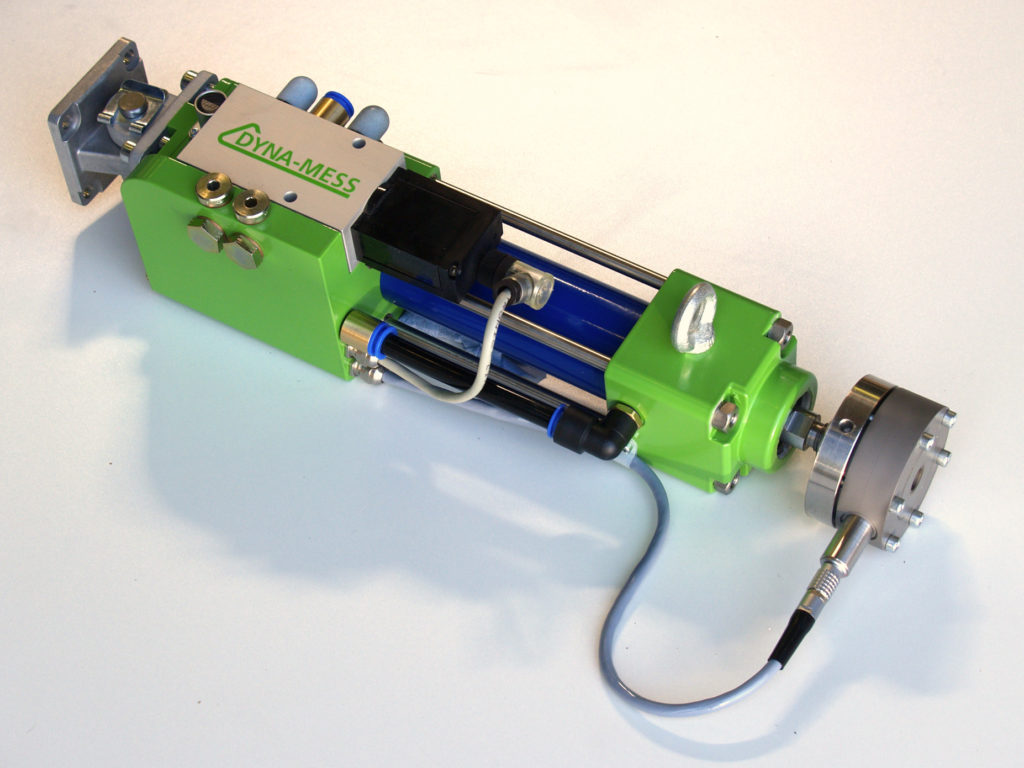

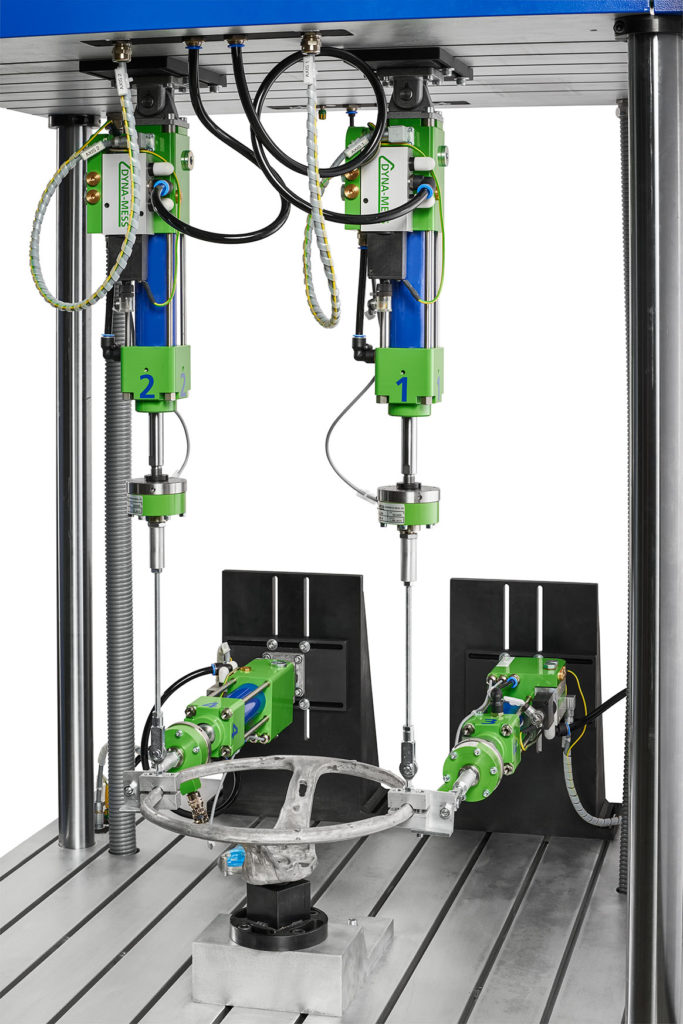

DYNA-BAT: Bi-axial tester

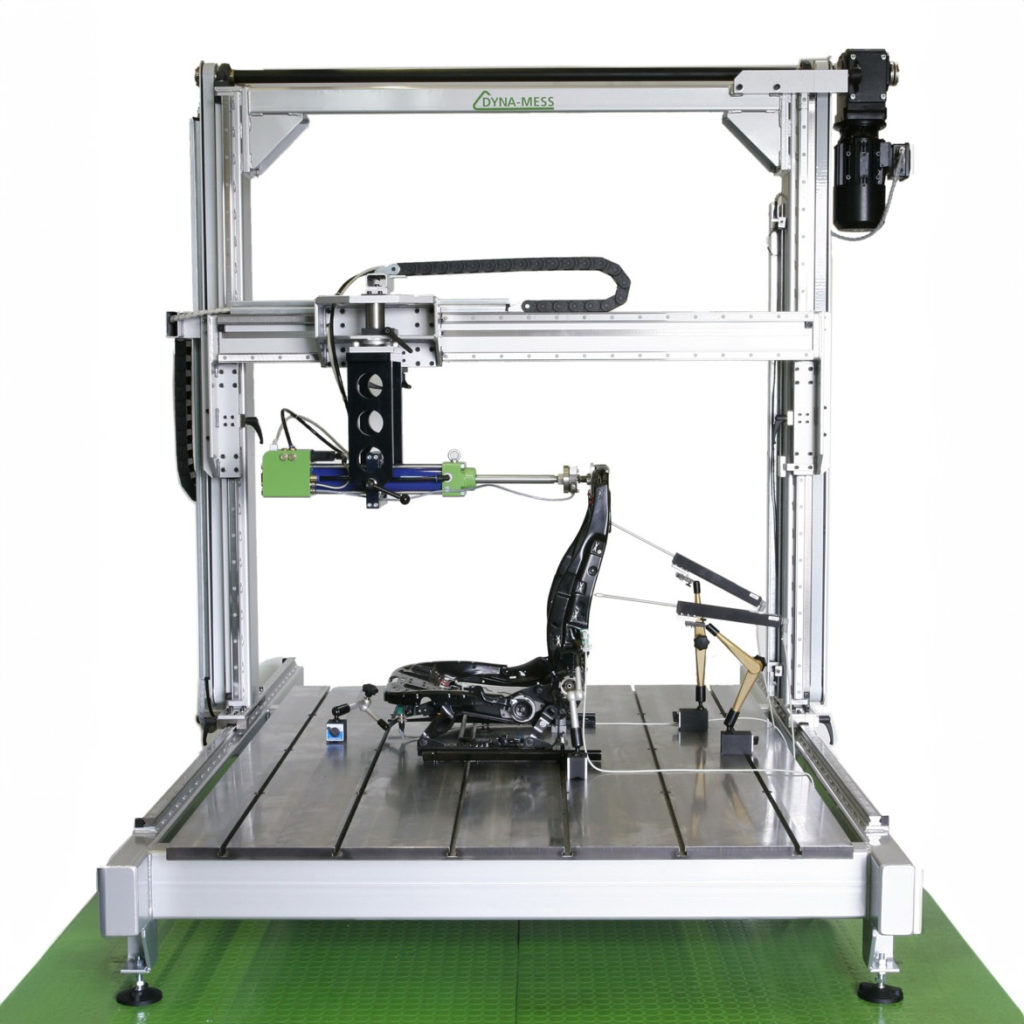

The DYNA-BAT steering wheel bi-axial tester is a test rig for car steering wheels. It offers the possibility of applying single-axis and multi-axes loads to a test specimen for fatigue testing.

We are DYNA-MESS. Test Systems.

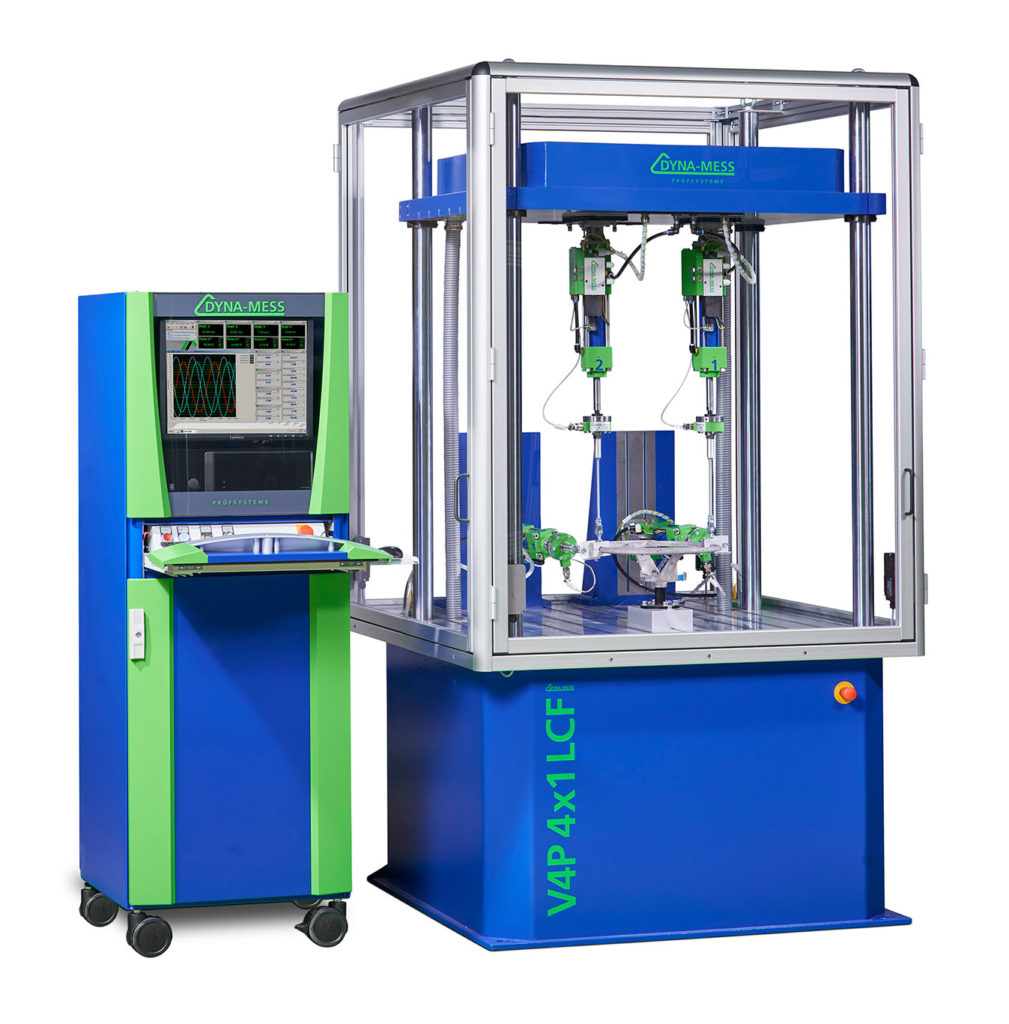

Technical properties

Combined mode

- Combination of up to four control loops with superimposed phase control

- Automatic break detection

- Continuous real-time data recording during the test

- Report with trend diagram “Load/displacement vs. cycles”

- Determination of the permanent deformation

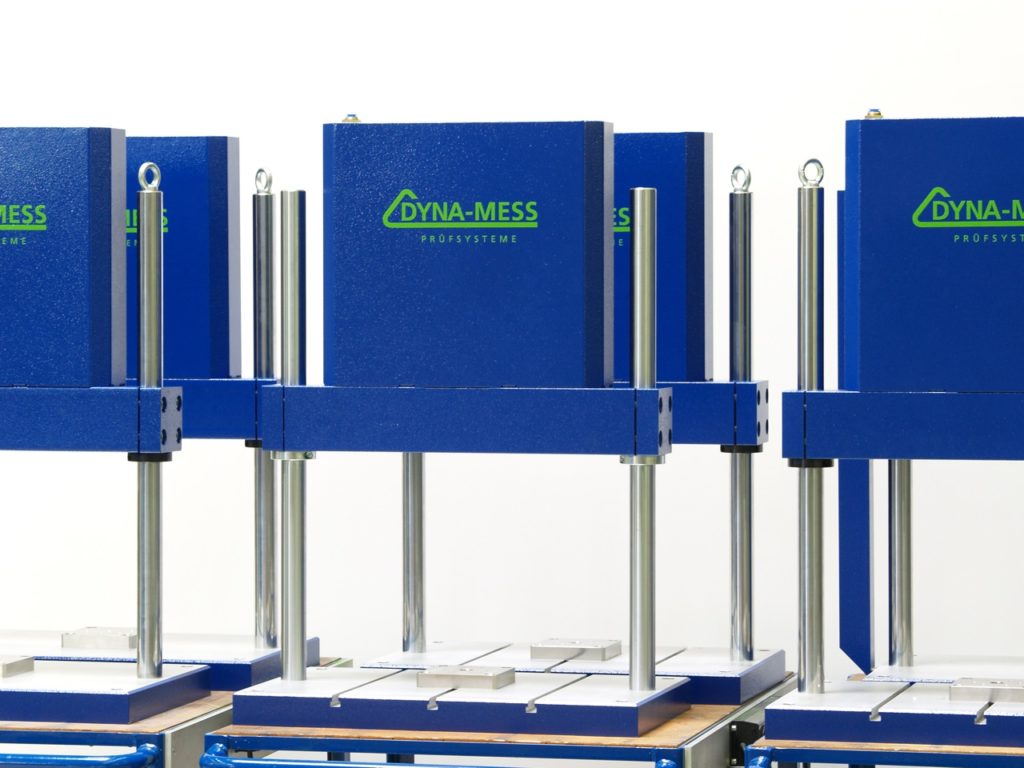

Single mode

- Testing of a maximum of four steering wheels

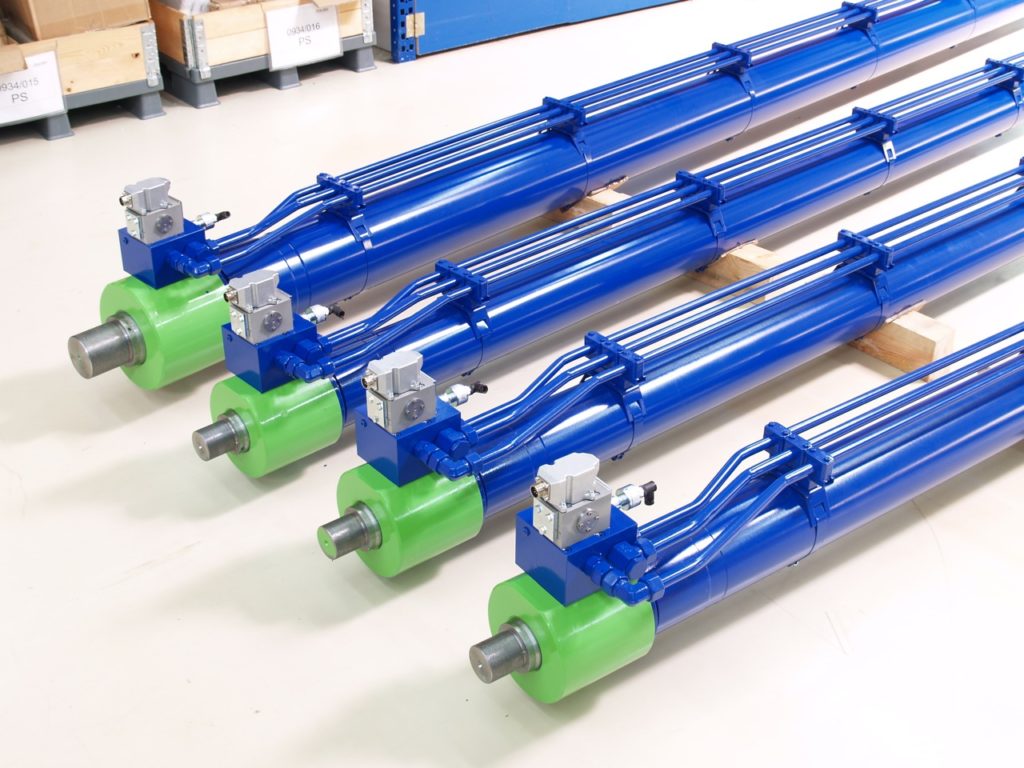

- Independent use of the actuator for individual operation

- Automatic break detection for each actuator

- Continuous real-time data recording during the test for each actuator

- Report with trend diagram “Load/displacement vs. cycles” for each actuator

- Determination of the permanent deformation

OUR SERVICES FOR YOU

Calibration

Adjusting test systems

Precisely calibrated for reliable measurement results and quality assurance

Maintenance

Maintain test systems

Professional maintenance for optimum performance and a long service life

Repair

Repairing test systems

Repairs for smooth operation and optimum performance

Modernisation

Test systems always up to date

Modern technology for improved performance and accuracy

Accessories

Upgrade test systems

Advanced functions and technologies complete testing machines

Training

Understanding test systems

User and topic training on all aspects of DYNA-MESS test systems